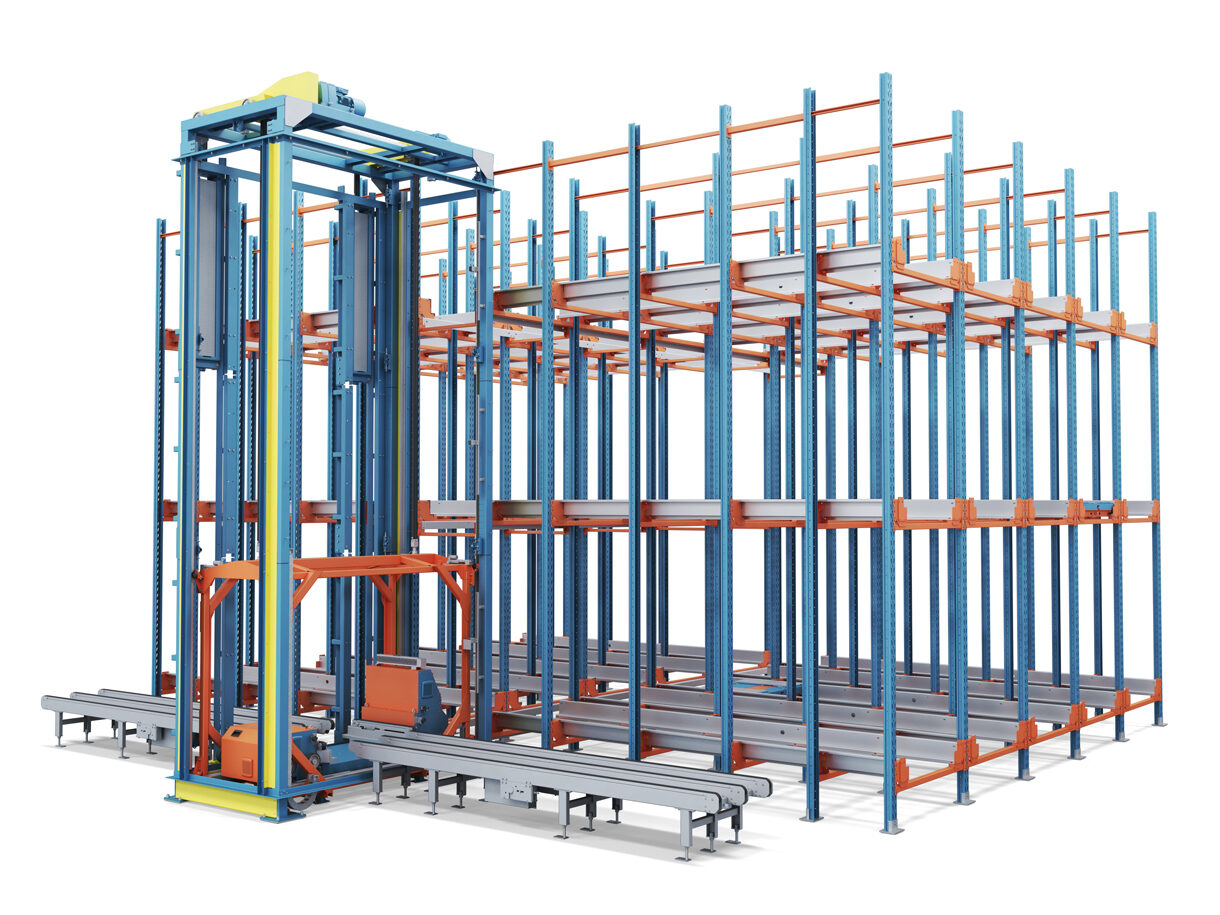

High-Density Automated Storage

WDX presents Q-Block, a fully automated high-density storage system. The system was designed by WDX engineers and is based on solutions manufactured by our company.

Q-Block is the easy way to a fully automated storage system:

- The basis of the system is the Q-Shuttle platform, which is used to move pallets inside the racking structure.

- The transport between the storage area and other storage areas is carried out by a system of conveyors and industrial lifts.

- The Q-Block can be individually adapted to each warehouse building. It can also replace an existing pallet racking system.

- Loading and unloading of the truck can be fully automatic – carried out by our ATLS system, the Q-Loader.

Scalable intralogistics automation systems

We implement intelligent warehouse automation systems. Our offer is addressed to companies optimizing their internal logistics processes and to integrators of intralogistics systems.

Send us your files for a quick quote – our engineers are ready for new challenges!

They trusted us: