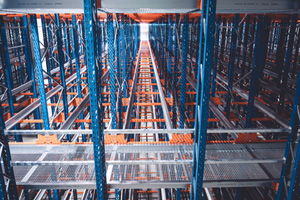

Live Pallet Racking

We offer pallet live storage system that guarantee a high level of warehouse space utilization – up to 80%. The X-PR Flow system guarantees precise warehouse management according to the FIFO principle.

The X-PR Flow optimizes workplace safety and reduces forklift cycle lengths. The transport of pallets in tunnels takes place with the help of gravity – from the sending point to the receiving point.

Highly recommended for:

- Production and distribution warehouses – especially in the food, chemical, and automotive industries.

- Enterprises where shelf life is crucial.

- Cold stores, freezers, and facilities where the cost of maintaining each m3 is relatively high.

Maximum standard height of a X-PR Flow system

Maximum standard length of a gravity tunnel

Maximum standard weight of a loading unit

Standard coefficient of facility space utilization

How does pallet live storage system work?

The base of the structure is a rack frame on which an angled rail with metal rollers is mounted. The rail attached to the frame creates a racking tunnel.

A forklift places the load down on the roller bed. The load moves in the tunnel with the help of gravity – the flow of goods takes place without additional drive.

The system can be retrofitted with systems to control the speed of the moving pallet. Pallet roller racks do not require any electrical components. Supply and receipt are clearly separated, which improves work organization.