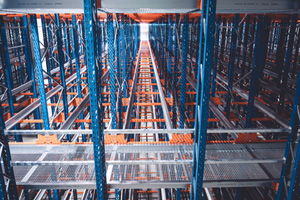

Intralogistics systems for warehouse cold stores and freezers

High investment and operating costs, harsh working conditions, maintaining established storage conditions with a high flow of goods, ensuring high product traceability, optimal use of available space and dynamically changing customer preferences are the main challenges faced by those managing a warehouse cold storage or freezer.