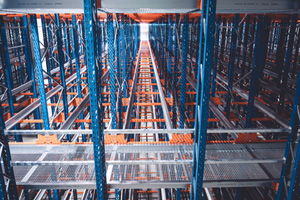

Pallet Shuttle Racking

The X-PR Shuttle is a cost-effective way to automate storage. It is possible to verify the forklift fleet size and the level of manpower utilization. Shuttle racks are distinguished by their very favorable cost-to-performance ratio.

Basic information on the X-PR Shuttle system:

- Particularly suitable for large quantities of fast-moving goods on uniform homogeneous loading units.

- The system, in its basic version, consists of a rack structure, a remote-controlled Q-Shuttle platform, and a control unit.

- Very high coefficient of space utilization – up to 90%. Multi-level structure in block tunnels translates into optimized storage costs per unit.